產(chǎn)品中心

Products

Products / 產(chǎn)品中心

Products / 產(chǎn)品中心

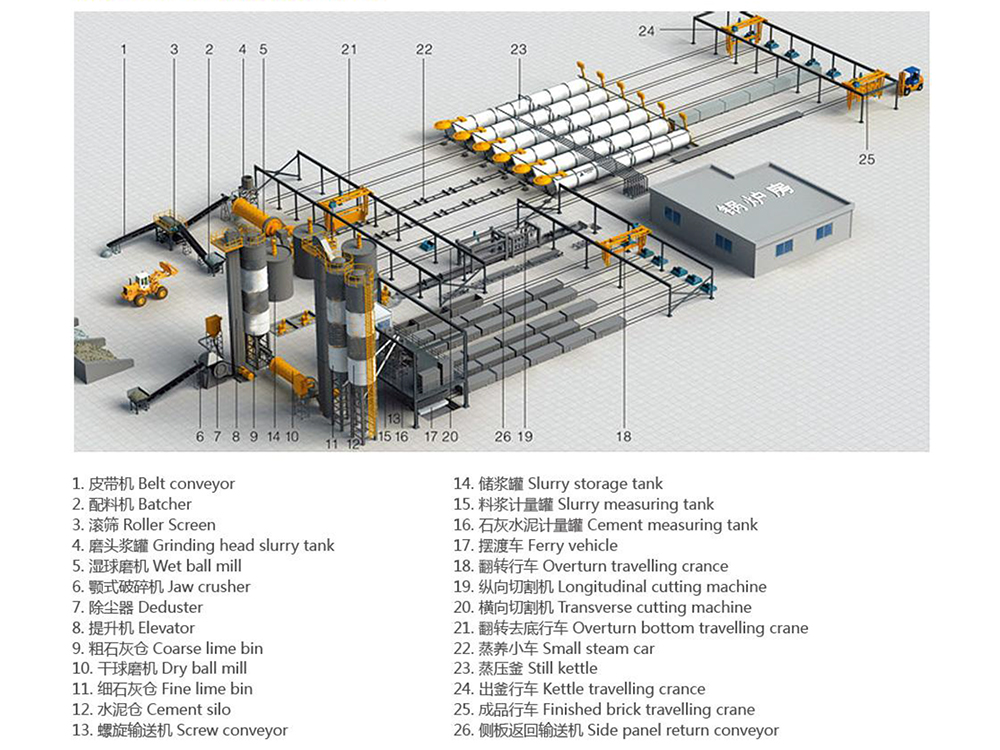

AAC Brick Making Machine Production Line

|

Equipment configuration

|

|||

|

(1)

|

Belt conveyor

|

(14)

|

Slurry storage tank

|

|

(2)

|

Batcher

|

(15)

|

Slurry measuring tank

|

|

(3)

|

Roller Screen

|

(16)

|

Cement measuring tank

|

|

(4)

|

Grinding head slurry tank

|

(17)

|

Ferry vehicle

|

|

(5)

|

Wet ball mill

|

(18)

|

Overturn travelling crance

|

|

(6)

|

Jaw crusher

|

(19)

|

Longitudinal cutting machine

|

|

(7)

|

Deduster

|

(20)

|

Transverse cutting machine

|

|

(8)

|

Elevator

|

(21)

|

Overturn bottom travelling crane

|

|

(9)

|

Coarse lime bin

|

(22)

|

Small steam car

|

|

(10)

|

Dry ball mill

|

(23)

|

Still kettle

|

|

(11)

|

Fine lime bin

|

(24)

|

Kettle travelling crance

|

|

(12)

|

Cement silo

|

(25)

|

Finished brick travelling crane

|

|

(13)

|

Screw conveyor

|

(26)

|

Side panel return conveyor

|

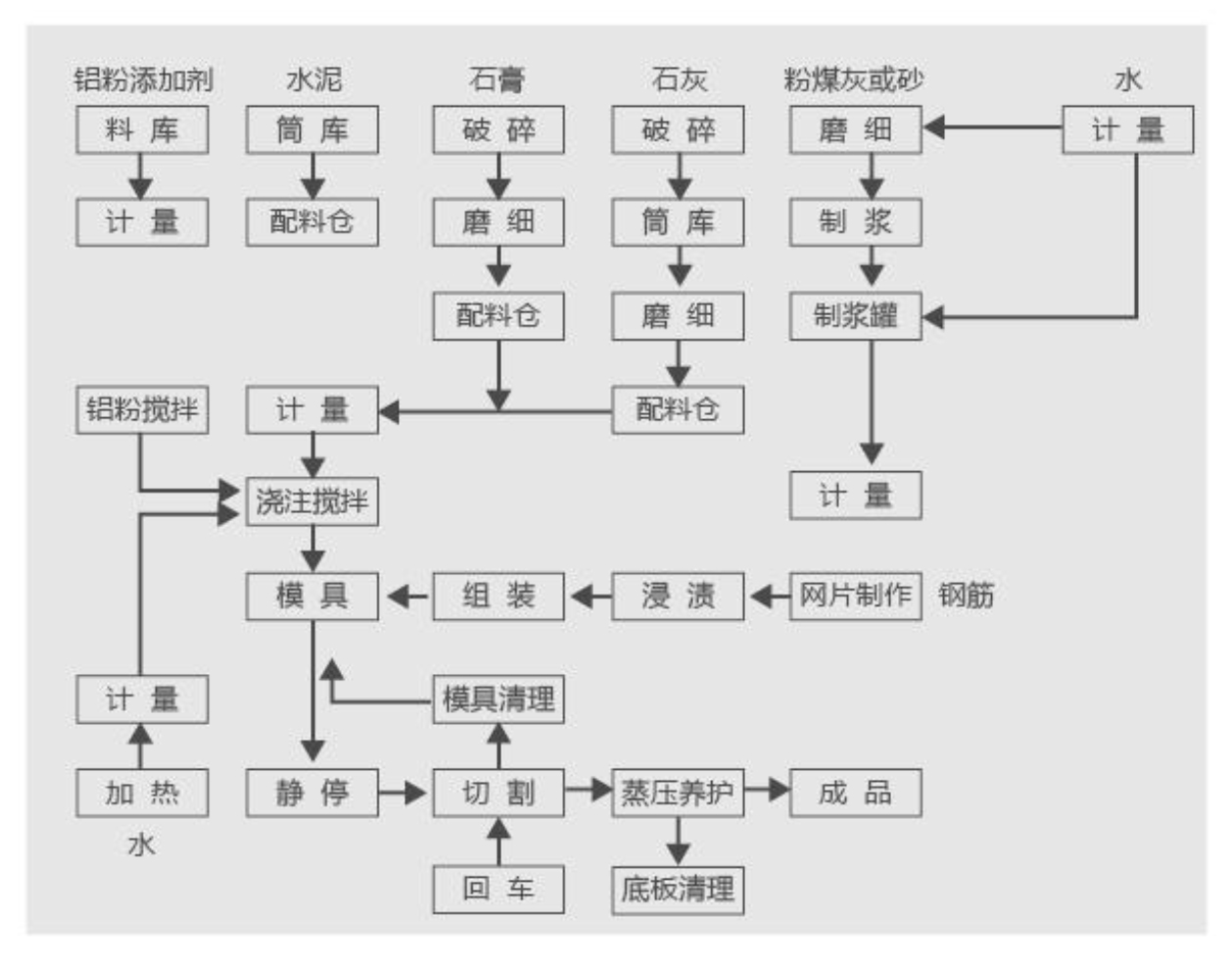

AAC Brick Making Machine Production Process Introduction:

Our company can produce and design yearly output 200,000-600,000 cubic meters fly ash AAC block production line and sand AAC block production line as various materials. Now we take fly ash AAC production line and sand AAC production line as an example to introduce its producing process.

Back

Back