產(chǎn)品中心

Products

Products / 產(chǎn)品中心

Products / 產(chǎn)品中心

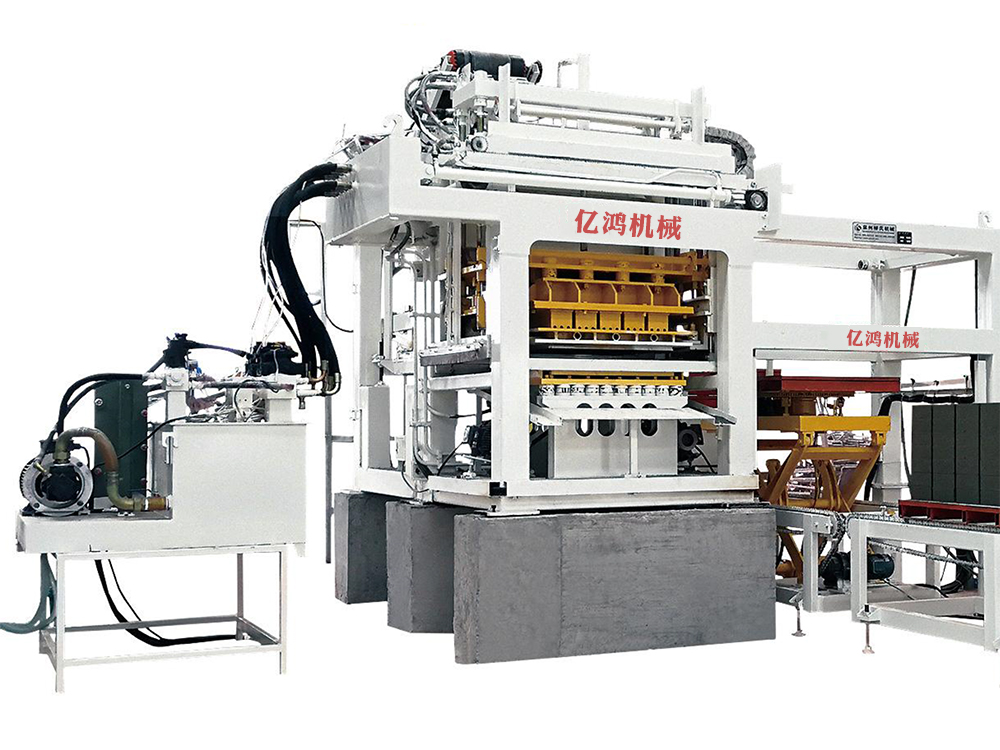

MT Free Pallet Brick Making Machine

(1) It does not need a pallet, also known as a brick machine without a pallet. It can be stacked now, saving the time and cost of pallet and loading and unloading.

(2) Rapid pressurization and high automation.

(3) The feeding car adopts double speed reduction motor design, and rotates to mix the material quantitatively at the same time. The speed of material distribution is fast and uniform.

(4) The synchronous driving of the material truck and the brick clamping air bag is applied to realize the flexible clamping and rapid movement of the product air bag without the support plate.

(5) The compactness of products is higher and more uniform.

(6) Reduce the friction coefficient of products under high pressure.

(7) The equipment runs more stably. At present, the pallet free brick machine produced by Yihong brick machine belongs to the third generation machine. It uses servo motor to move the mold, and the lifting table is equipped with a decoder.

(8) The support free brick machine equipment is independently developed by Quanzhou Yihong brick machine and has the patent right. It is an outstanding one in Quanzhou brick machine industry and has a very high market share.

(9) In order to meet the needs of the majority of users to pack the bricks sold, the factory also specially developed a special brick receiving line for the non pallet brick machine; The utility model can realize the effect of collecting and stacking the brick stacks formed by the pallet free brick machine, and can reserve the forklift hole position; At the same time, it can also be used with the automatic packing machine, so as to give play to the greater equipment advantages of the plate free brick machine.

2.Producing capacity table:

|

Brick size

|

QTY / mould

|

Forming cycle

|

Brick sample

|

|

390×190×190mm

|

8 pieces

|

18~22S

|

|

|

240×50×115mm

|

42 pieces

|

18~22S

|

|

|

240×90×115mm

|

18 pieces

|

18~22S

|

|

3.Technical parameters:

|

Item |

Parameter |

Values |

Total |

|

Main machine |

Oil pump motor |

18.5 (KW) |

61.05 (KW) |

|

Vibratory motor |

2×11 (KW) |

||

|

Mixer motor |

3 (KW) |

||

|

Conveyor belt motor |

3 (KW) |

||

|

Pallet conveyor motor |

2.2 (KW) |

||

|

Block conveyor motor |

2.2 (KW) |

||

|

Sub bracket motor |

1.1 (KW) |

||

|

Bracket motor |

1.1 (KW) |

||

|

Rotary table motor |

0.75 (KW) |

||

|

Blender |

Main mixing motor |

18.5 (KW) |

25.1 (KW) |

|

Lifting motor |

5.5 (KW) |

||

|

Water pump motor |

1.1 (KW) |

||

|

Batching machine |

Electric machinery |

3×4 (KW) |

12 (KW) |

|

Cement spiral pipe |

Electric machinery |

7.5 (KW) |

7.5 (KW) |

|

Cable |

Lead wire |

90 (mm2) |

Optional |

|

Copper core wire |

50 (mm2) |

||

|

Transformer |

Power ratio |

50~70 (KVA) |

|

|

Workshop |

Area |

25m(long)×12m(width) |

300㎡ |

|

Rest room |

Area |

300~400(㎡) |

Make adjustments according to the customers investment plan |

|

Total power: |

101.95 (KW) |

||

|

Molding area |

870×870mm |

Tray specification |

900×900mm |

|

Molding method |

Platform mould combined vibration |

Exciting force |

90KN |

4.Raw materials and uses:

Raw materials: Water washed sand mud, sludge, solid waste, sand, stone, construction waste, cement, and a large amount of industrial solid wastes such as fly ash, slag, steel slag, coal gangue, ceramsite and perlite can be added.

Purpose: In general, the non pallet brick machine is only used to produce cement solid bricks, porous bricks, etc. at present, it is not recommended to use the non pallet brick machine to produce thin-wall hollow bricks and color bricks. The supporting free brick machine has natural advantages in treating solid wastes such as construction waste, industrial and mining waste, etc; In addition, in the metallurgical refining industry, the pallet free brick machine can also be used as a pelletizing machine to press the scattered mineral powder, slag and mineral powder into a pellet, providing basic conditions for secondary refining!

Matters needing attention:

(1) At present, no pallet free brick machine is used to produce thin-wall hollow bricks and color bricks; Before purchasing the pallet free brick machine, you should first inform the relevant person in charge of Quanzhou Yihong brick machine!

(2) If water washed sand mud is used to make bricks or sludge is used to make bricks, the raw materials shall be dried as much as possible; The more dry the mud material, the better the brick making, and the content of mud can be more!

返回列表

返回列表