產(chǎn)品中心

Products

Products / 產(chǎn)品中心

Products / 產(chǎn)品中心

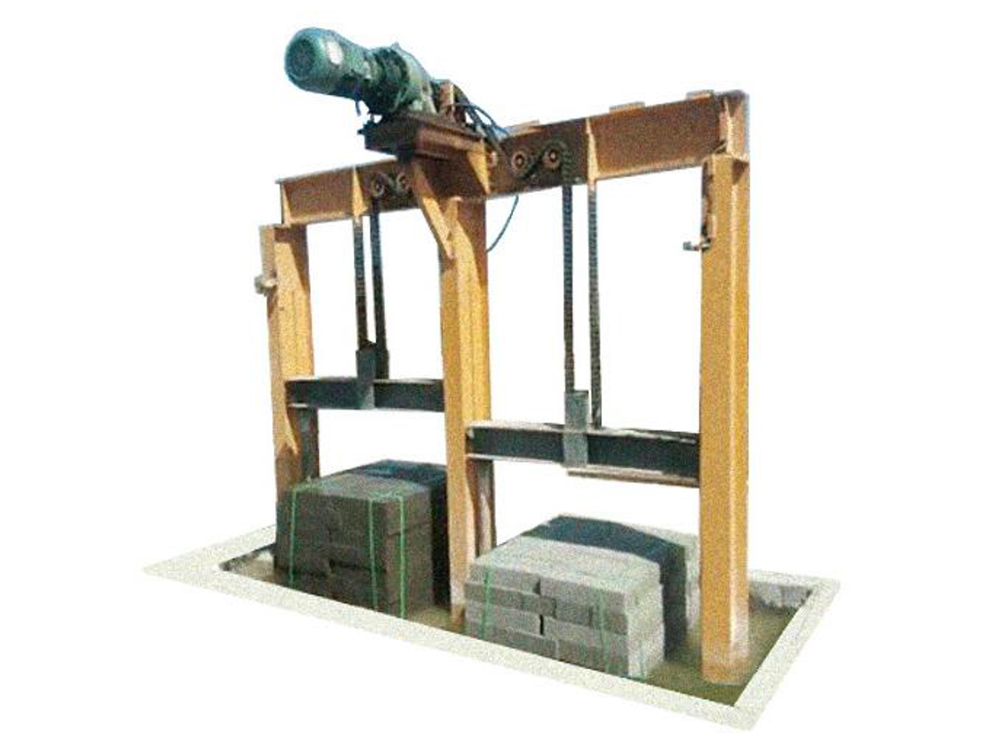

Automatic Soaking Machine

Main advantages and functions:

1. The automatic soaking machine for non burning bricks is equipped with two 3T hoists and 24 flat guide wheels, which can realize the stable lifting of two lifting frames; Simple structure, easy to use, easy to maintain and low maintenance cost.

2. This equipment can separate and stack the blocks of different specifications produced by different models of brick machines. After stacking, the whole stack shall be transported to the storage yard by forklift for curing, and the pallet less stacking can also be realized by cooperating with the forklift clamp, and the bricks can be directly loaded; The labor cost is greatly saved, and the whole system needs only one person to operate.

3. In addition, bricks are indispensable in construction. As the bricks are relatively dry, the bricks need to be soaked before use, and the soaked bricks can only be used. In the past, the bricks were directly put into the water for soaking. Because the soaked bricks require relatively wet humidity, it is easy to wet clothes and site when they are salvaged; Moreover, it also consumes more labor costs to fish one brick at a time. The automatic soaking machine for non burning bricks can not only fully soak bricks, but also realize automation.

4. This type of automatic soaking machine for unburned bricks adopts PLC automatic control, and adjusts the soaking time for different bricks to realize automatic soaking of various stacked bricks. In the process of soaking, the transportation mode of pallets stacking is adopted as a whole, which is quite stable and avoids the problem of brick breaking due to shaking and collision, and solves the problem of cement brick soaking in water and brick soaking in building construction, realizes the automation of brick soaking and effectively reduces the manual strength.

1. The automatic soaking machine for non burning bricks is equipped with two 3T hoists and 24 flat guide wheels, which can realize the stable lifting of two lifting frames; Simple structure, easy to use, easy to maintain and low maintenance cost.

2. This equipment can separate and stack the blocks of different specifications produced by different models of brick machines. After stacking, the whole stack shall be transported to the storage yard by forklift for curing, and the pallet less stacking can also be realized by cooperating with the forklift clamp, and the bricks can be directly loaded; The labor cost is greatly saved, and the whole system needs only one person to operate.

3. In addition, bricks are indispensable in construction. As the bricks are relatively dry, the bricks need to be soaked before use, and the soaked bricks can only be used. In the past, the bricks were directly put into the water for soaking. Because the soaked bricks require relatively wet humidity, it is easy to wet clothes and site when they are salvaged; Moreover, it also consumes more labor costs to fish one brick at a time. The automatic soaking machine for non burning bricks can not only fully soak bricks, but also realize automation.

4. This type of automatic soaking machine for unburned bricks adopts PLC automatic control, and adjusts the soaking time for different bricks to realize automatic soaking of various stacked bricks. In the process of soaking, the transportation mode of pallets stacking is adopted as a whole, which is quite stable and avoids the problem of brick breaking due to shaking and collision, and solves the problem of cement brick soaking in water and brick soaking in building construction, realizes the automation of brick soaking and effectively reduces the manual strength.

返回列表

返回列表